Advanced dimensions such as flush and gap, profile radius, airfoil dimensions (leading edge, trailing edge, and global), assembly clearance, thickness, and more.Feature dimensions and GD&T controls (ASME Y14.5-2009 and ISO 1101, as well as PTB certified 64-bit/32-bit).Surface, boundary, and cross-sectional measured-to-nominal deviations.PolyWorks | Inspector delivers the complete toolbox you need to extract and analyze:

Nominal dimensions can also be extracted from a CAD model or a reference measured part. Thanks to the remarkable flexibility integrated into PolyWorks, dimensions can be extracted from measured point clouds, polygonal models built from point clouds, or probed points.

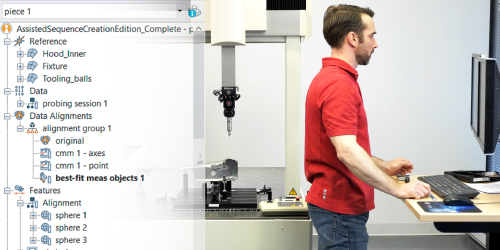

PolyWorks | Inspector is a powerful industrial 3D metrology software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using non-contact point cloud digitizers and single-point contact-based probing devices. Capability Studies & Statistical Analysis.

0 kommentar(er)

0 kommentar(er)